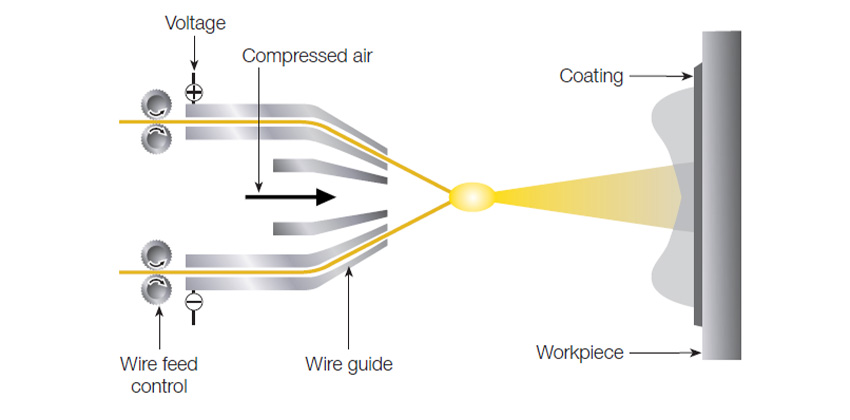

Process Details

- Wire electrodes fed

- Electric arc melts wire

- Compressed air atomizes metal

- Molten droplets propelled forward

- Particles impact substrate surface

- Coating builds layer-by-layer

- Final surface finishing applied

Wire Arc Spray Process

W

i

r

e

A

r

c

S

p

r

a

y

P

r

o

c

e

s

s

The wire arc electric spray process, also referred to as the electric arc process, involves the use of two consumable wire electrodes that are connected to a high-current direct-current (DC) power source. These electrodes are fed into a spray gun where they meet and establish an arc between them. The intense heat from the arc melts the tips of the wires, which are then fed into the gun using either an electric-driven motor or an air motor. The molten metal is subsequently atomized and propelled toward the substrate by a stream of compressed air. This process is highly efficient because the wires are directly melted by the arc, resulting in a thermal efficiency significantly higher than that of other thermal spray methods

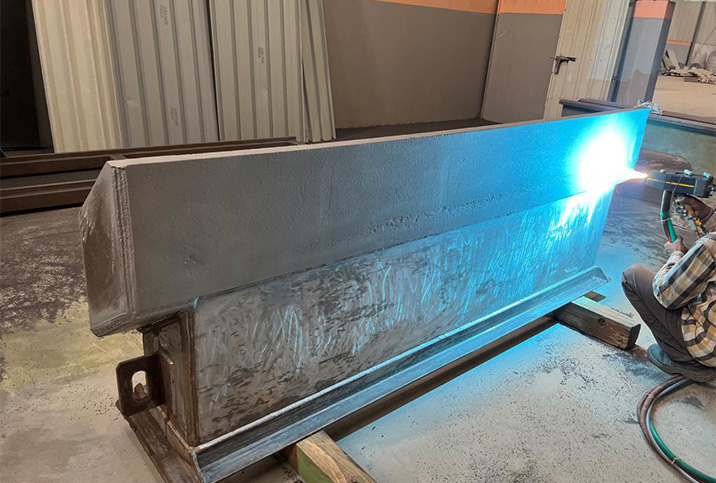

- Transportable process, spraying on location possible

- Micro porous lamellar structure

- Excellent adhesion and density of the coating

- Versatile and reliable

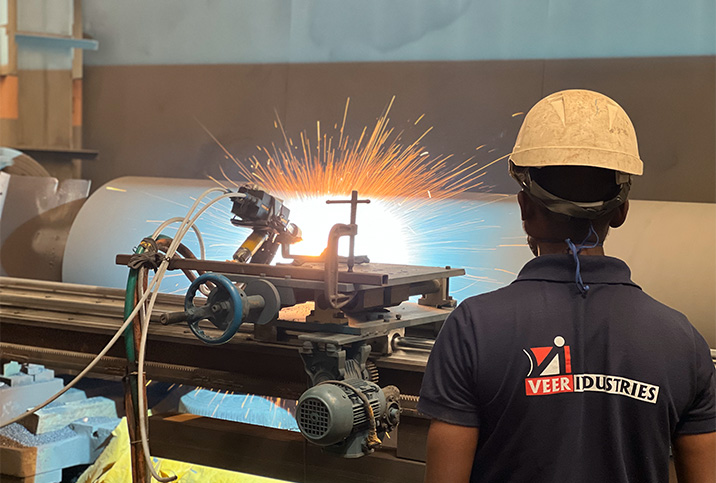

- High production capacity

- Wear and Erosion

- Abrasion

- Hard Chrome Replacement

- High Temperature Environments

- Corrosion Resistance

- Atmospheric Environments

- Chemical Environments

- Friction Engineering for Fretting

- Anti-skid/Traction

- Tribological Coatings

- Dimensional Restoration of parts requiring repair

- Various stainless steel alloys

- Monel

- Inconel

- Hastelloy

- Tin

- Nickel-based alloys

- Copper and copper alloys

- Aluminium

- Zinc

×

❮

![]()