Ceramic Industries

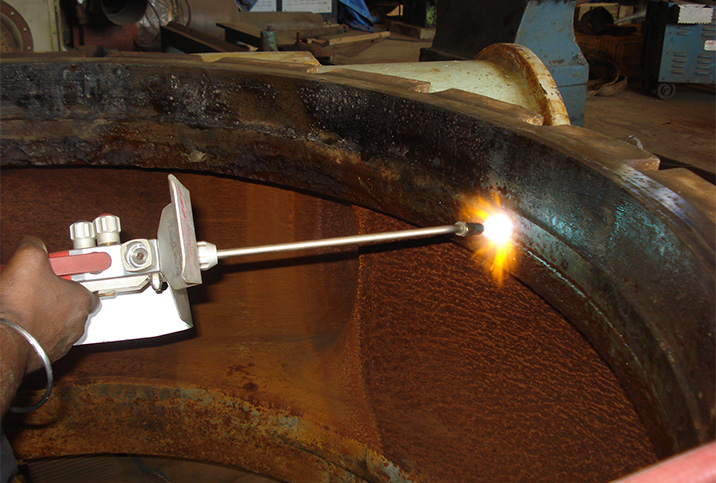

In the ceramic industry, common issues such as wear, dragging, erosion, and corrosion frequently affect machine components like barrels and pistons. These challenges are often compounded when wear occurs in highly corrosive environments, making the problem even more complex. Applying a Hard chrome plating & thermal sprayed coating to these components can significantly enhance properties like cycle life, capacity, and maintenance cost reduction.

It has become increasingly common to upgrade older installations with lightweight materials to boost production capacity. This approach helps older facilities remain competitive with newer installations, ensuring continued efficiency and productivity. VEERCOAT completed more then 150 piston & barrel in last 5 Years.

Components

- barrels

- pistons

- Equipment Parts

- shaft

Features

- Improved Wear Resistance

- Enhanced Corrosion Resistance

- Thermal Barrier and Insulation

- Increased Surface Hardness

- Improved Adhesion to Substrates

- Cost-Effectiveness

- Customization and Versatility

- Non-Destructive Process

- Reduced Thermal Shock Sensitivity

- Environmental and Wear Protection

- Minimized Surface Porosity