Thermal Power

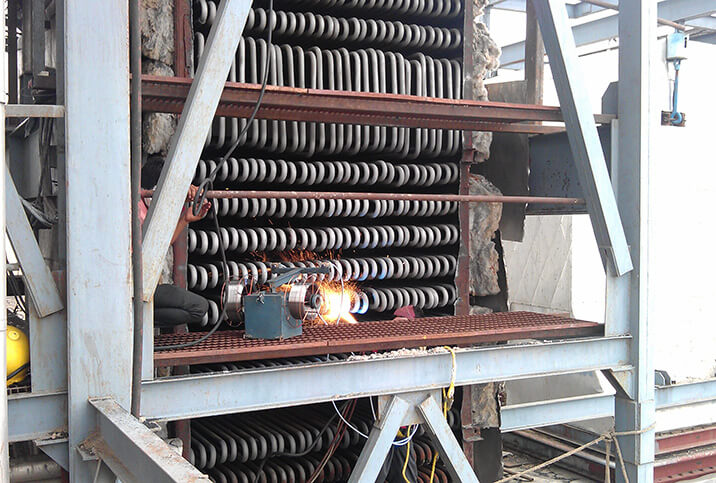

Thermal power plants are a primary source of electricity generation through the combustion of coal. These power plants utilize various types of coal, often with high ash content. The presence of high ash and sulfur levels in the coal leads to increased erosion and corrosion on the boiler tubes.

VEER COAT specializes in the manufacturing of steam turbine valve internals for Original Equipment Manufacturers (OEMs). These components are engineered with advanced coatings and hard-facing/cladding techniques (utilizing cobalt and nickel-based materials) to significantly enhance their performance and extend their service life. We proudly supply these critical components to renowned organizations such as BHEL (Haridwar and Varanasi) and Siemens, among others.

Additionally, we offer refurbishment and repair services for steam turbine rotor bearing journals through the innovative Thermal Spray Process. Our state-of-the-art facility in Ahmedabad, India, is equipped with robotic coating technology, precision grinders, and advanced machine tools with a Digital Read-Out system to ensure the highest levels of quality and accuracy in all our operations.

We offer two processes for boiler tube coatings and have customized Nano material feedstock in form of wire & powder.

- Twin Wire Arc Spray (TWAS)

- High Velocity Oxy Fuel (HVOF)

Components

- Valve Cone

- Valve Spindle

- Valve Cone with Spindle

- Valve Stems

- Valve Seat & Disc

- Diffuser

- Threaded Ring

- Bushes

- Guide Bushes

- Angle Rings

- Pulverized Fired Boiler (PF Boiler)

- WHRB / Chemical Recovery Boilers

- Oil/Gas Fired Boilers

- CFBC Boiler

- AFBC Boiler

Features

- Enhanced Durability

- Improved Efficiency

- Cost Savings

- Environmental Resistance

- Corrosion Protection