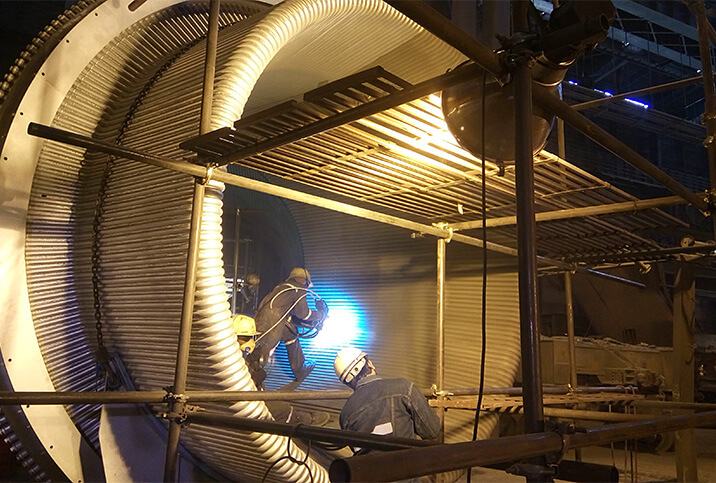

Roll Manufacture

VEERCOAT INDUSTRIES PVT LTD, founded in 2009, is a recognized leader in the manufacturing of high-quality precision custom rollers. As a one-stop shop for any size , any types of rollers, we are committed to delivering exceptional quality and precision in every product we offer.

With years of accumulated engineering and manufacturing experience, our R&D-driven business model has propelled our steel roll shop to become a competitive global supplier, backed by patented technologies. To date, we have successfully manufactured over 1200+ rolls featuring Hard Chrome Plating, Tungsten Carbide Coating, and Spray & Fuse coatings.Rolls for various steel production lines are manufactured in our plant :

- Continuous Annealing (CAL/CAPL)

- Skin Pass Mill (SPM)

- Electrolytic Cleaning Line (ECL)

- Batch Annealing Furnace (BAF)

- Recoiling Line (RCL)

- Wire Rod Mill (WRM)

- Cut To Length Line (CTL)

- Colour Coating Line (CCL)

- Continuous Galvanizing Line (CGL)

- Thin Slab Caster Roll (TSCR)

- Pickling Line & Tandem Coating Mill

- Pellet Plant

The rolls manufactured at VEERCOAT are equipped with advanced protective coatings that enhance their operating life and efficiency. The selection of coating materials and processes is the result of a combination of in-house R&D and valuable inputs from global technology partners. These solid, fabricated, or cast rolls undergo high-tech robotic coating in state-of-the-art acoustic spray booths, ensuring optimal performance.

Rolls Manufactured at VEERCOAT:

- Bridle Roll

- Deflector Roll

- Flattener Roll

- Burr Musher Roll

- Deburring Roll

- Hold Down Roll

- Leveller Roll

- Looper Roll

- Pass Line Roll

- Pick Up Roll

- Pickling Roll

- Quenching Roll

- Tensiometer Roll

- SDRS & DDRS Roll

- Wringer roll

- Tension roll

- Steering roll

- Pinch roll

- Guide roll

- Table roller

- Feed roller

- Wrapper roll

- ACBR Roll

- Back Up Roll

- Accumulator Roller

- Squeeze Roller

- Applicator Roller

- Snubber Roller

Features

- Rolls are resistant to impact and wear, making them suitable for a wide range of applications.

- A variety of coating materials tailored to meet diverse application needs.

- Precision finishing of rolls as per specific requirements.

- Achieving hardness, roundness, concentricity, ovality, and surface finish within the prescribed tolerances.

Advantages

- Longer lifespan, resulting in reduced downtime and increased production output.

- Lower maintenance costs.

- Exceptional wear resistance.

- Superior slippage resistance properties.

×

❮

![]()